Projects

Filter ProjectsValvoline Headquarters

Valvoline’s new headquarters was designed to celebrate their heritage as a leader in racing while simultaneously capturing their focus on technology and product innovation. The decision to use precast concrete was made because for a project such as this, it is unparalleled when compared with different frameworks. The double-return panels give this building an alluring quality, highlighted its geometry, and was also financially attainable and able to be produced within an anticipated timeframe.

Reading K-12 School

The Reading Community Schools made the decision to combine its three individual schools into one school that would house 15,000 students. The owners worked with an architect to design the school with a traditional look using brick and limestone trim. The architect, Earl Crossland, was able to achieve that look using precast concrete.

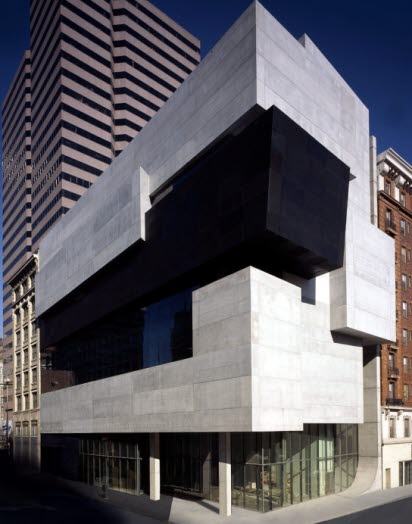

Rosenthal Center for Contemporary Art

The new home of Cincinnati's Contemporary Arts Center embodies the institution's ongoing role as promoter of daring and farsighted artistic strategies. In that creative spirit, the ingenuity of High Concrete Group contributed to the completion of the award-winning building.

Founded in 1939 as the Modern Art Society, the Center was one of the first institutions in the United States dedicated to exhibiting contemporary art, and has always included design and architecture in its mandate. Consistent with its probing of the outer limits of the current art scene, the Center, under the leadership of Director Charles Desmarais, selected Pritzker Prize-winning architect Zaha Hadid to design its new facility: The Lois and Richard Rosenthal Center for Contemporary Art. It is the first major American museum designed by a woman. Hadid remains on the cutting edge of Deconstructivist architecture, both challenging and, in her own way, responding to context.

The unique modern art museum is primarily made of precast concrete wall panels that were fabricated and installed by High Concrete Group’s Springboro, Ohio facility. High was selected for the complex project because of its reputation and experience with high-end architectural concrete. Working closely with the architect, High Concrete designed 140 spandrel panels for the 82,265 square-foot building.

Overall, in a building dedicated to creativity, it is only fitting that High’s functional and aesthetically pleasing panels helped the Rosenthal Center truly become a work of art.

New Brunswick Transit Village

In a recent and unconventional interpretation of this concept, the New Brunswick Development Corporation (Devco) has completed Gateway Transit Village, a mixed-use, transit-oriented design consisting of a 24-story building and a new pedestrian walkway directly adjacent to a NJ Transit/Amtrak station. Located in the heart of downtown New Brunswick across from the Rutgers University campus, the new $150 million, 632,000-square-foot structure is the tallest parking garage and building in the city. A precast parking structure from High Concrete Group LLC forms its core.

Built as part of an ongoing revitalization effort, the new complex is intended to help bring renewed life to a site that is vital to the city, but that has been under-utilized for many years. With views of the Raritan River, the apartments and condos in the tower are targeted to attract people who already live and work in New Brunswick. Twenty percent of the units are set aside for moderate- and low-income owners.

The project is unconventional in several ways. "Gateway is the most urbanly dense transit village in New Jersey," notes David J. Stuart, project manager for New York City-based Meltzer Mandl Architects. "Everything that’s normally incorporated into a transit village has been combined into a single structure."

"Also, precast concrete parking garages are not typically designed to support taller and more complex structures above them; they are usually stand-alone buildings. To place a 14-story building on top of a garage is daring structural engineering," says Stuart.

Gateway Transit Village consists of a 10-story precast parking garage with 697 parking spaces, topped by a 14-story steel-frame and hollowcore residential tower containing 150 apartments and 42 condos. The structure is wrapped by 120,000 square feet of offices and a series of street-level commercial spaces for tenants, including the Barnes & Noble College Bookstore for Rutgers and offices for the New Brunswick Parking Authority and the Rutgers University Press.

Stuart notes that Gateway Transit Village doesn’t relate to its context as much as redefine it. "A typical approach would be to hide the parking garage, and disguise the precast," says Stuart. "At first we considered thin brick, to match other parts of the structure. But we decided that we wanted an exposed concrete aesthetic for the podium, to let concrete be concrete, and to show its inherent nature. Precast concrete can be quite elegant, minimalist. It was economical, fast, and gave us pleasing aesthetics."

The majority of the garage was cast in a standard High Concrete Group buff architectural mix and finished with a light sandblast. Simple reveals set up a rectangular pattern that brings scale to the horizontal spandrels and complements the openings between them on the way up. Spandrels at the top are finished with a small cornice.

The parking garage required 24-foot and 36-foot spacing between the support walls to optimize the parking spaces and 12’-wide precast double tees. The residential tower called for a different supporting grid, which had to have its column lines aligned with the garage support walls via 10-inch-thick hollowcore plank spanning up to 36 feet.

"This is a good use of precast," says J. Benji Alper, PE of engineering firm Severud Associates’ New York office. "While the precast garage is only 10 stories, the overall structure still stands at 24 stories tall, requiring the precast walls to resist the forces for the full lateral and gravity loads of the 24-story building." He discusses the approach in the Structure Magazine article,"Integration of Diverse Structural Systems and Design Delegation in a Mixed Use Space."

Alper notes that communication was critical in the project. "Immediately after the contract award, weekly meetings were conducted with the entire design team which included members from the precast manufacturer’s engineers, the structural engineer, the architect, the parking consultant, the owner, and the general contractor. Other trades, including the steel fabricator, the steel detailer, and the erector, also would often attend. The meetings were a key part of an iterative design process between Severud and High Concrete Group."

Academy of World Languages

The strikingly attractive building features several complementary finishes within each panel. Exposed aggregate provides bold texture and an earthiness that befits the school’s wooded surroundings. A subtle, uniform sandblast finish appears alongside an acid etched treatment that deepens colors for contrast and imparts a stone-like appearance. Horizontal lines of vibrant ruby red tiles below crimson-framed windows add contrast across the façade, while vertical lines of blue tiles almost make the seam between panels an aesthetic feature. Finally, insets of alternating yellow and blue tile provide a visual counterpoint to the exterior light fixtures directly above them. Overall, it’s a colorful, vibrant exterior that reflects the energy and discovery of learning.

Merrill praised the aesthetic versatility of precast. “It allowed us to play with colors and textures, maintaining a simple yet still attractive building,” he said. “We were able to gain economies through repetitive patterning and use scale and massing to keep the building interesting and not overwhelming to the kids.”

The benefits extended to the interior walls as well. The precast sandwich wall panels were prefinished on the inside with paint filler and institutional grade paint. Durable concrete will withstand decades of heavy use and abuse from energetic children. Furthermore, the prefinished interior eliminated the expense and time that a field-constructed interior would have entailed.

NJIT Student Housing

When new student housing was required at an urban New Jersey college, precast concrete was the first and only choice. As a new cornerstone landmark for the campus, the design needed to be one that would both accommodate and represent the tech forward, innovative student body. With the next generation beginning their college selection process, students want single occupancy rooms and amenities that make student housing feel more like a home. This student housing offers bicycle storage, underground parking, a game room, creative space, lounge space, a grass courtyard, and indoor and outdoor cafes.

Villanova University Pedestrian Bridge

This collegiate pedestrian bridge harmonizes with a collegiate campus that has been around for years. The environment of a college tends to develop around them, causing a need to adapt. Taking something that was, “a necessity and turning it into an asset” was an added benefit to the Architect. Ultimately plastic and versatile, precast concrete helps designers realize their vision even when it’s not the hero in the visual. In this project, harmony, and consistency with the campus aesthetic was a high priority to both the University and the designers. To achieve this goal, the design included a fieldstone veneer to the exterior of the precast bridge following erection except for the architectural panels over the road. The panels over the existing road had the fieldstone applied by the precast manufacturer to the panel prior to being transported to the location. This helps cut down road closure time and boost efficiency.

Ohio State University Chiller Plant

Recent trends in chiller plant design that have been to use eye-catching enclosures, often glass boxes, to allow mechanical systems to be visible from outside. However, this presents the problem of cooling the chiller plant. At Ohio State University in Columbus, Ohio, a new ten-story plant uses precast concrete panels with a series of openings that allow a view inside, while keeping the interior temperature consistent and the energy use regulated.

The plant building is more than just a concrete box with openings, however. Conceived as a “House for Energy,” the envelope showcases the energy-efficient chiller equipment inside and records the sun’s energy on the exterior.

The LEED Silver Certified building features a high-polish finish and “fins” of diachronic glass that cast colored light rays across the concrete surface. The result is a dynamic façade that changes with the time of day, season, and location of the observer.

The chiller housed at the new plant facility provides chilled water production and distribution to the medical center area of the campus. The plant encloses the equipment used to maintain 12,500 tons of chilled water, with a plan to increase that capacity to 30,000 tons. Emergency power installed at the plant increases the reliability of the water production and distribution in the event of a power outage.

5th and Race

The new mixed-use structure at 5th & Race Street in Cincinnati, Ohio, gives visitors the impression that they can see right through the building. Designers of the 280,000 ft² facility, elegantly merged broad windows and precast concrete panels to create a light and elegant building that reflects the blue sky during the day, and golden street lights at night, while giving residents a strong, open space for their offices and retail.

The building, titled 84.51° Centre, includes a 1000-space, four-story parking garage at the base topped by four stories of commercial space. Precast concrete was chosen to achieve the owners’ durability, accelerated timeline, and aesthetic goals, says Glenn Ebersole, P.E., Market Development Manager of High Concrete Group, the precaster on the project. “By using architectural precast panels we were able to provide the dark color and avoid the repetitiveness of patterns while limiting erection time.” The dark color of the precast concrete was created by combining black granite coarse aggregate with black sand in the mix. The panels were acid etched to provide a soft texture, sometimes referred to as sugar cube texture. The acid etch finish also enables the sand to sparkle in the sun, providing glints of light and visual interest to passersby.

“The use of precast to provide ventilation on the garage level helps camouflage the fact that the lower levels of the building are a garage and it creates a unified facade,” says Michael Zensen, Associate Vice President, CannonDesign, one of the judges of the 2016 PCI Awards committee. The horizontal reveal pattern provided the desired modern, industrial look, and random non-symmetrical window openings combined with reveal accents added visual interest.

FDNY Firehouse Rescue #2

Located in a city neighborhood, the FDNY rescue facility was designed for an elite force of specialized rescue workers to stage and simulate a wide range of emergency conditions. The members of the rescue company train to respond to various emergency scenarios, including fires, building collapses, water rescues, and scuba operations.

Lancaster County Convention Center

Big building, small space

Established in 1718, Lancaster is the oldest inland city in the United States. Its town square can be traced back to 1730 when James Hamilton laid the city out in a traditional grid. Structures with lasting, historical value have been fixtures on the square for years. The central area has always been among the most densely developed parts of the city.

Certainly, constructing an intricate project, Lancaster County Convention Center, that would bring new architecture to an established, compact downtown would require imagination and thoughtful planning. Knowing that precast could solve many of the potential issues, architectural firm Cooper Carry engaged High Concrete Group LLC from the earliest planning stages.

The biggest obstacle consisted of working around the existing structures, many of which would be integrated into the new complex. It severely limited the size of the construction site. Because precast is manufactured off-site and delivered to the job as needed, it was preferable over field-built options that would have required significantly more space.

“Staging was a big issue,” explains Kevin Iddings, general manager of Midwest operations for High Concrete Group. “We developed a regimented schedule that allowed us to ship the precast pieces one at a time as they were needed. It helped avoid a backlog of materials in the field.”

In addition, High worked with the architect to simplify the job as much as possible, eliminating unnecessary pieces and identifying ways to reuse molds, thereby minimizing costs.

Integration

TQL Ivy Pointe Office

The TQL Ivy Pointe Office building is predominately thin brick-clad with light sandblasted buff-colored precast details framing the spandrels. The precast provides a face-sealed curtainwall that provides effective moisture control that typical rain screen construction cannot. The thin brick is finished with a rake joint. Additional precast details include a 2-1/2’ projection below the parapet to lend a dramatic shadowline. The parapets themselves are at a height of 42” over the roofline to allow maintenance and other personnel to work on the roof without tying off.

The design made repeated use of a few stacked panel designs, allowing maximum economy. L-shaped thin bricks wrapped around window returns as would a full depth brick course. Formliner created a stone look formliner to the columns at the main entrance to add to the feeling of solidity. Reveals add drama and break up the mass to create a human scale.

Villanova Performing Arts Center

When planning to construct a new performing arts building, Villanova University weighed the many options for construction materials. As part of the University’s project to transform a previously underutilized parking lot into a multi-use area, including student housing, retail, and dining, the performing arts center acted as the crown jewel of the development. Through this development project, the University intended to provide the local metropolitan community an opportunity to experience new forms of art and culture, while also using the facility as a hands-on learning experience for theatre students. To achieve this vision, the structure needed to house a full-size theater, along with studios and classrooms, and provide adequate acoustic isolation between the spaces. Villanova is known for its Gothic-style architecture across campus, so the new design also had to complement the aged architectural style of its surroundings. Creating precast panels with plant-installed stone could meet the aesthetic and functional needs of the university with lower costs and construction time than a traditional stone façade.

CUA Conway School of Nursing

A University in Washington D.C. needed a new state-of-the-art building for its school of nursing, and it was important to the client to maintain the look of the existing gothic architecture on its campus. This was a design assist/build project consisting of 60,000 square feet of precast panels and copings on a steel frame structure and 30,000 square feet of post-installed thin veneer stone.

Precast concrete was chosen for this project due to the complex aesthetic design features, schedule, and site constraints. Using precast concrete is a modern construction method that can provide the complex institutional athletics of the surrounding campus buildings while being able to take advantage of the various schedules and site benefits of precast construction.

The University is a campus with an existing Gothic architecture style. It was very important to keep the new building in the same design style as the current surrounding architecture throughout the campus. Stone was applied at the precast producer’s plant to the panels to match the aesthetics of the other campus buildings. The stone that was used in this project was salvaged and recycled from a demolished Catholic Church, which is both symbolically relevant as well as a completing sustainability feature.

Aside from the design, a reason to choose precast for this project was the location of the project and the need to stick to a strict schedule. The building is located adjacent to a busy public street that could not be shut down for long periods of time, Due to precast being produced offsite and ready to install when arriving on site, traffic disruptions were limited, and the schedule was able to be maintained to allow students to use the building on time. This 102,000 square foot nursing education facility will serve the students at this University for years to come.