Precast Concrete Engineers Make It Real!

Outer Beauty, Durable Inner Strength

Versatility and safety make Precast a favorite

From the versatility of the product and to the safety both on-site as well as the durability, precast concrete is a favorite for all engineers. Capable of accommodating a wide variety of configurations, thanks to its versatility, precast concrete can maximize open areas and create flexible options that please both design and structural integrity.

Due to precast concrete’s design versatility, the design allows for the use of fewer materials in creating the structural system than other construction methods. This aids in minimizing costs for clients, design time for an architect, and durability for engineers.

Precast is a design rich medium

Aesthetic Versatility

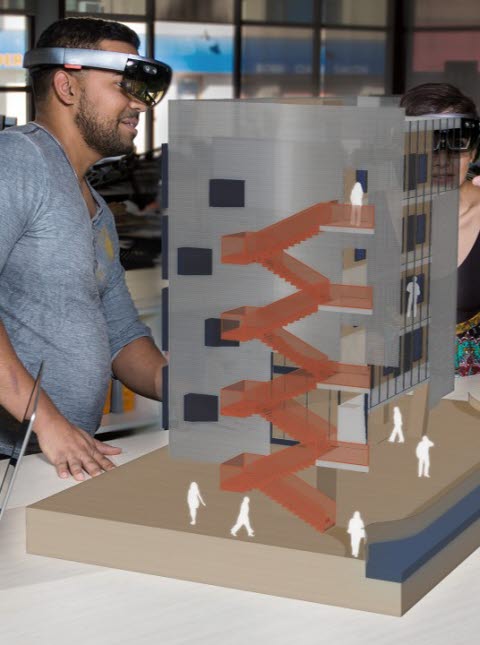

Precast excels in durability, strength, versatility, on-site safety makes Precast a favorite for Engineers and Architects. Precast is capable of a wide variety of configurations that satisfy both aesthetic and structural integrity requirements. The off-site-build of precast components mitigates weather factors and reduces site logistic issues. Precast's versatility reduces materials, and construction time, while increasing durability, and structural integrity.

Scroll through the images to view multiple design methods.

Click Learn More below to see additional information on aesthetics

Site Efficiency and Adaptability

For today and the future

Less is more when it comes to site efficiency. Simply put, precast concrete means less waste and better on-site safety.

- Less Workers = Better/Easier Coordination

- Fewer Trades = Minimal Management and Transactions

Because building components are prepared off-site, precast is inherently more efficient than other methods. Work on-site can move forward until the precast is needed. Then it can be delivered and picked off a trailer and placed into its spot on the structure. Also, with so much emphasis being placed on project life cycles, engineers can use precast concrete to create an adaptable shell that can be changed during decades of service.

Structure Durability

Safety in Design

Savvy Engineers know precast concrete structures will resist external threats such as hurricanes, tornadoes, earthquakes, and fire. This makes precast the safest solution in situations where wind-borne flying objects at tornado speeds and fire resistance/containment are required.

Precast concrete meets all FEMA P-361 criteria for safe rooms and the material is non-combustible with a slow rate of heat transfer. Also, precast is utilized to help with 500-year flood plains. In the case of the Statue of Liberty Museum and screening facility, precast was used to help combat hurricane flooding on the island. Read more about it in the project profile here.

Featured Projects for Engineers

1200 Intrepid

2016's Harry H. Edwards Industry Advancement Award winner proves that precast concrete enables the most innovative architectural designs while providing a highly energy-efficient and durable envelope. One of

Nassau 8th Precinct

Following Hurricane Sandy in 2012, many structures owned by Nassau County in New York state were evaluated for structural damage, including the police precincts. Prior to the storm...

Penn State Hershey Campus Parking Garage

Inspired by the rolling hills in Pennsylvania, the eye-catching waving spandrels are the first element to greet you as you drive onto the health campus and the last

80 on the Commons

The playful yet sophisticated use of a herringbone pattern results in a standout, bold style that NBBJ wanted to capture on this civic asset in the city’s central open space.

ELEVATE YOUR PRECAST DESIGN.

Have a question about our precast design options? That's what we are here for. Reach out to our team of precast design engineers with any questions or details about your project and we will get back to you.