The Future of Concrete

The Future of Concrete

Where Are We Heading?

Concrete has existed in many forms for thousands of years. From the Pantheon in Rome to the Sydney Opera House, concrete continues to demonstrate both longevity and architectural creativity as a building material. In fact, one of the earliest examples is a hydraulic limestone cement used by the Nabataean people starting around 700 BCE.

Make no mistake, the concrete of today is not that of yesterday. As demand continues to increase for nearly all kinds of construction, emerging technologies in concrete offer unique solutions that other building materials just can’t match. The future of precast concrete offers affordable, sustainable, and fast construction. Here, we highlight some of the latest technologies that are driving the precast concrete industry forward.

Improvements to Concrete Production

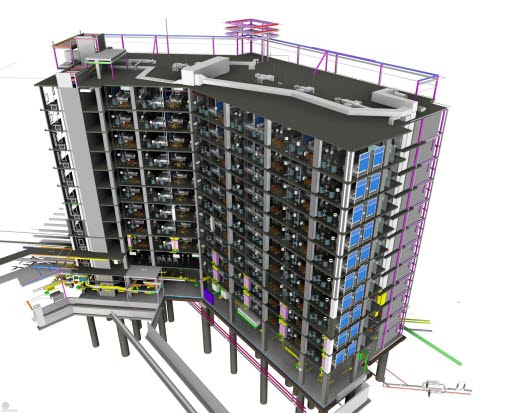

As digital and mechanical technologies improve, they can be applied to the methods for producing precast. 3D modelling has improved vastly throughout the digital age, and Building Information Modelling (BIM) is evidence of that progress. When creating a BIM, the model can store data across systems so all details of a project can be accessed in one place. This makes every step from idea inception to design to the final product more efficient, saving time and reducing the risk of errors. For precast concrete, BIM offers up-to-date, accessible information that is communicated to and from production throughout the entire project. Incorporating BIM technology ensures accuracy from ideation to build, which helps keep costs low and projects on schedule.

As 3D printing has also improved, the ability to do so with concrete has emerged as an efficient and sustainable way to build. The process takes place by pouring layers of concrete according to digital plans and specifications. 3D printing concrete creates no product waste and can be used to prefabricate entire buildings at an affordable cost. The process dramatically reduces price and construction time, making it ideal for affordable housing. 3D printing has also been extremely beneficial for creating precast silicone or rubber molds since they can be fully customized and reused for future projects.

Making Concrete Stronger and More Resilient

Ultra-High-Performance Concrete (UHPC) has been in use since 1980 and is becoming increasingly available. Typically only used in infrastructure projects such as bridges, UHPC has compressive and tensile strength that is 2-10 times greater than traditional concrete, with a projected lifespan of 100 years. Because it is so strong, the material has the added benefit of requiring less maintenance and structural complexity. The potential for application in other kinds of structures makes precast UHPC a major innovation in cost and efficiency across building sectors.

The development of self-healing concrete can also improve the longevity of concrete structures. Because the smallest crack can result in the deterioration of steel reinforcement and the concrete’s integrity as a result, immediately filling any damage is necessary to maintain a structure. Mixing bacteria that biologically produce limestone with concrete, when exposed to the atmosphere through a crack, allows the bacteria to produce healing limestone that fills the damaged area. These bacteria can live for as long as 200 years within the concrete, so this option is ideal for small to medium sized structures that are intended for long-term use.

Discovering New Possibilities of Concrete

Innovations in concrete are even creating new abilities for the material. One way is through the incorporation of light-emitting cement into concrete. By converting the microstructure of cement to a gel form through polycondensation, solar energy can be absorbed during the day and released as light for up to 12 hours each night. This cement can be added to a concrete mixture and then be used for highways, bridges, and walking paths that require illumination. Because no electricity is needed, light-emitting concrete provides a sustainable alternative when lighting is needed outdoors. The cement also has a lifespan of about 100 years, meaning that if the concrete itself is maintained, structural upkeep will be limited. As this technology advances, it may be applied to parking structures, commercial or residential buildings, and more.

Precast concrete has many benefits: minimal on-site labor, accelerated construction, high durability, and low costs. As the technology continues to improve, concrete will become even more versatile and efficient.

Interested in learning about our precast innovations at High Concrete Group? Contact one of our sales representatives today!

Sources:

Building Information Modeling - National Precast Concrete Association

What is Ultra-High Performance Concrete (UHPC)? (uhpcsolutions.com)

Light-Emitting Cement: A Sustainable Way to Light up Highways - The Constructor

Reach Out to Our Team