Projects

Filter Projects8 item(s) found.

Mercy Health West Hospital

Opened in fall 2013, Mercy Health - West Hospital brings a new level of healthcare to Cincinnati's west side. The 625,000sf project features 250 beds, comprehensive cardiac care, an oncology treatment center, a maternity and birthing center, and Ohio's largest green roof. The medical facility eliminates the need for the local residents to travel outside of the area for full-service medical care.

The medical facility features state-of-the-art care combined with amenities that focus on the patient and their families to create a comfortable and healing atmosphere. This approach to health care architecture, balancing beauty, culture and function set a new standard for hospital design. Connections between architecture, natural light, and landscape promote healing.

Located on a 60-acre wooded site, the hospital's large diagnostic and treatment base is designed to co-locate surgery, imaging, the emergency department, and cardiovascular ICU. Two-bed towers sit on this platform, which features a living roof covered with native plants — providing an ever-changing view from the patient rooms above.

The unique, 107,000sf green roof covers 2.5 acres and has more than 65,000 plants. Patients and visitors can enjoy views of the roof from the patient towers, as well as an observation area. The roof helps maintain cooler building temperatures during summer months, while capturing and holding 75% of rainwater, thus lessening the amount of stormwater run-off.

Christ Hospital

In 2012, the Christ Hospital Network in Cincinnati, Ohio, decided to add an orthopedic center of excellence to its already nationally renowned healthcare facility. The owners worked with an architect to design the seven-story, 381,000 ft2 LEED Silver-certified Joint & Spine Center, which linked it directly to the hospital’s existing surgical and imaging areas.

As part of the broader master plan, the client and architect agreed that the design for the Joint & Spine Center needed to reflect the historical redbrick vernacular of the other campus buildings. It also had to meet strict budget restrictions, deliver a watertight building envelope, and meet the high-performance goals set for the new building. All of these requirements would be met with a precast concrete design.

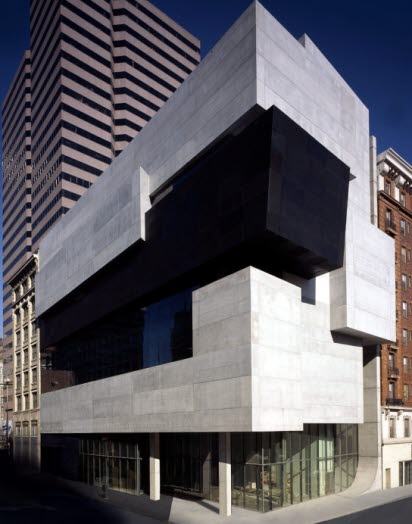

Rosenthal Center for Contemporary Art

The new home of Cincinnati's Contemporary Arts Center embodies the institution's ongoing role as promoter of daring and farsighted artistic strategies. In that creative spirit, the ingenuity of High Concrete Group contributed to the completion of the award-winning building.

Founded in 1939 as the Modern Art Society, the Center was one of the first institutions in the United States dedicated to exhibiting contemporary art, and has always included design and architecture in its mandate. Consistent with its probing of the outer limits of the current art scene, the Center, under the leadership of Director Charles Desmarais, selected Pritzker Prize-winning architect Zaha Hadid to design its new facility: The Lois and Richard Rosenthal Center for Contemporary Art. It is the first major American museum designed by a woman. Hadid remains on the cutting edge of Deconstructivist architecture, both challenging and, in her own way, responding to context.

The unique modern art museum is primarily made of precast concrete wall panels that were fabricated and installed by High Concrete Group’s Springboro, Ohio facility. High was selected for the complex project because of its reputation and experience with high-end architectural concrete. Working closely with the architect, High Concrete designed 140 spandrel panels for the 82,265 square-foot building.

Overall, in a building dedicated to creativity, it is only fitting that High’s functional and aesthetically pleasing panels helped the Rosenthal Center truly become a work of art.

Riverside Hospital Neuroscience Tower

The Riverside Hospital Neuroscience Tower project is a 10-story, 437,000-square-foot addition to an Ohio Health campus. The project is the only one of its kind and is a state-of-the-art, world-class brain and spine care destination. The project includes 224 private rooms and a large interior atrium the size of two full-size basketball courts.

The exterior features 72,390 ft2 white, precast concrete panels as well as a series of blue-tinted, vertical windows. This was done to resemble the other buildings on the campus. These buildings were built at different times, with different materials, but many feature white brick walls surrounding vertical rhythms of windows. “We wanted to stay away from bricks,” said the architect. “They have an institutional connotation and can make a building appear bigger.”

Precast panels were utilized on the exterior of the building to cover a substantial portion of the facade. Precast was also used to clad a large portion of an interior courtyard that began at the third level of the structure with a rooftop green space/garden area and concluded seven stories higher at the penthouse level.

Ohio State University Chiller Plant

Recent trends in chiller plant design that have been to use eye-catching enclosures, often glass boxes, to allow mechanical systems to be visible from outside. However, this presents the problem of cooling the chiller plant. At Ohio State University in Columbus, Ohio, a new ten-story plant uses precast concrete panels with a series of openings that allow a view inside, while keeping the interior temperature consistent and the energy use regulated.

The plant building is more than just a concrete box with openings, however. Conceived as a “House for Energy,” the envelope showcases the energy-efficient chiller equipment inside and records the sun’s energy on the exterior.

The LEED Silver Certified building features a high-polish finish and “fins” of diachronic glass that cast colored light rays across the concrete surface. The result is a dynamic façade that changes with the time of day, season, and location of the observer.

The chiller housed at the new plant facility provides chilled water production and distribution to the medical center area of the campus. The plant encloses the equipment used to maintain 12,500 tons of chilled water, with a plan to increase that capacity to 30,000 tons. Emergency power installed at the plant increases the reliability of the water production and distribution in the event of a power outage.

80 on the Commons

The playful yet sophisticated use of a herringbone pattern results in a standout, bold style that NBBJ wanted to capture on this civic asset in the city’s central open space.

Continuing in the style of the black façade on the top eleven stories, the white panels at ground level begin with linear lines and gradually fade to a smooth finish. The transition from a smooth finish to a heavily textured panel gives the ground level a clean ordered look in contrast to the beauty of the organized chaos above. The white mix used as the deep contrast is captured throughout the façade from the balconies to the back of the building’s recessed design were all achieved using precast concrete.

Scattered among the levels are cantilever balcony decks protruding straight out from the structure of the building. No support brackets or elements are needed for these precast slabs due to the design, therefore providing the visual of a floating deck. The severe contrast of the two colors helps deliver the architect's design intent.

The result of the refined material palette and texture of the pattern used is one of the unique features of the building. The custom formwork makes the surface appear as if it is changing throughout the day due to the shadow with the sun. Depending on the angle, the layout gives off an impression where sections appear as different shades of a black concrete mix, when in fact, it’s not.

5th and Race

The new mixed-use structure at 5th & Race Street in Cincinnati, Ohio, gives visitors the impression that they can see right through the building. Designers of the 280,000 ft² facility, elegantly merged broad windows and precast concrete panels to create a light and elegant building that reflects the blue sky during the day, and golden street lights at night, while giving residents a strong, open space for their offices and retail.

The building, titled 84.51° Centre, includes a 1000-space, four-story parking garage at the base topped by four stories of commercial space. Precast concrete was chosen to achieve the owners’ durability, accelerated timeline, and aesthetic goals, says Glenn Ebersole, P.E., Market Development Manager of High Concrete Group, the precaster on the project. “By using architectural precast panels we were able to provide the dark color and avoid the repetitiveness of patterns while limiting erection time.” The dark color of the precast concrete was created by combining black granite coarse aggregate with black sand in the mix. The panels were acid etched to provide a soft texture, sometimes referred to as sugar cube texture. The acid etch finish also enables the sand to sparkle in the sun, providing glints of light and visual interest to passersby.

“The use of precast to provide ventilation on the garage level helps camouflage the fact that the lower levels of the building are a garage and it creates a unified facade,” says Michael Zensen, Associate Vice President, CannonDesign, one of the judges of the 2016 PCI Awards committee. The horizontal reveal pattern provided the desired modern, industrial look, and random non-symmetrical window openings combined with reveal accents added visual interest.

TQL Ivy Pointe Office

The TQL Ivy Pointe Office building is predominately thin brick-clad with light sandblasted buff-colored precast details framing the spandrels. The precast provides a face-sealed curtainwall that provides effective moisture control that typical rain screen construction cannot. The thin brick is finished with a rake joint. Additional precast details include a 2-1/2’ projection below the parapet to lend a dramatic shadowline. The parapets themselves are at a height of 42” over the roofline to allow maintenance and other personnel to work on the roof without tying off.

The design made repeated use of a few stacked panel designs, allowing maximum economy. L-shaped thin bricks wrapped around window returns as would a full depth brick course. Formliner created a stone look formliner to the columns at the main entrance to add to the feeling of solidity. Reveals add drama and break up the mass to create a human scale.